Description

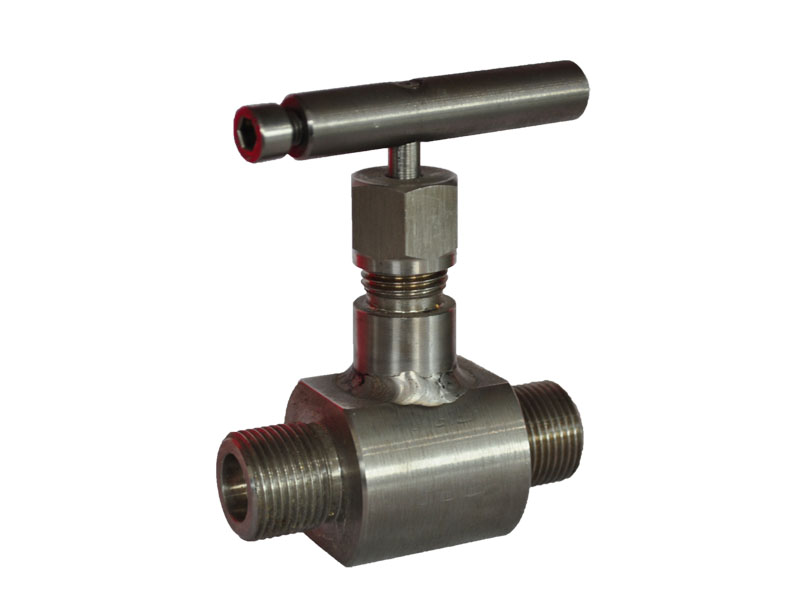

- Due to the high degree of tightness, needle valves are used both in liquid and gaseous media. Needle valve is designed for engineering inspection, it is applied in differential manometers on heat engineering lines. The name "manometric" reflects the specific application of the valve.

- The valve shutter is made in the form of a conical needle. Such shutter shape allows to ensure high tightness of the device. Due to high degree of tightness, needle valves are used for both liquid and gaseous media.

MAIN TECHNICAL CHARACTERISTICS:

|

Valve type |

DN, mm |

PN, MPa (kgf / m2) |

Flow passage ø, mm |

|

15с / лс /нж54бк |

6, 10, 15, 20, 25, 32, 40, 50 |

to 16 (160) |

4 |

|

15с/лс/нж/л67бк 68бк |

to 40 (400) |

6 |

- Working environment: water, steam, liquid and gaseous hydrocarbons and their mixtures, as well as other working media, in relation to which the materials of the main valve parts are corrosion-resistant.

- It is forbidden to use the valve for viscous media transferring.

- The flow passing through the valve should be relatively clean, because foreign particles can contaminate the valve opening.

- The operating temperature is determined by the material of the body parts:

Steel 20, St.09 G2S - up to 350 ° C;

St. 12Х18Н10Т - up to 550 ° С;

Brass - up to 200 ° С. - Ambient class - Normal1 and Tropical1 according to State Standard 15150-69

- Hermetically sealed valves shutter belong to class A of State Standard 9544.

Durability and tightness of the valves is confirmed by testing on a special certified stand. - Connection to the pipeline: flanged, true union, welded, choke house (male), choke-nipple.

- Manual actuation

- Warranty - 12 months.

- Working lifespan not less than 10 years.